Page 955 - Motor protection and control Manual motor starters, contactors and overload relays

P. 955

ABB MOTOR PROTECTION AND CONTROL 13/17

—

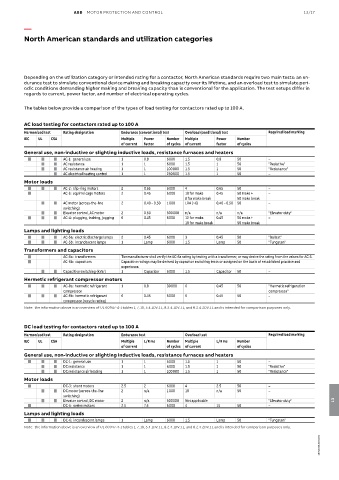

North American standards and utilization categories

Depending on the utilization category or intended rating for a contactor, North American standards require two main tests: an en-

durance test to simulate conventional device making and breaking capacity over its lifetime, and an overload test to simulate peri-

odic conditions demanding higher making and breaking capacity than is conventional for the application. The test setups differ in

regards to current, power factor, and number of electrical operating cycles.

The tables below provide a comparison of the types of load testing for contactors rated up to 100 A.

AC load testing for contactors rated up to 100 A

Harmonized test Rating designation Endurance (conventional) test Overload (conditional) test Required load marking

IEC UL CSA Multiple Power Number Multiple Power Number

of current factor of cycles of current factor of cycles

General use, non-inductive or slighting inductive loads, resistance furnaces and heaters

AC-1: general use 1 0.8 6 000 1.5 0.8 50 –

AC resistance 1 1 6 000 1.5 1 50 "Resistive"

AC resistance air heating 1 1 100 000 1.5 1 50 "Resistance"

AC electrical heating control 1 1 250 000 1.5 1 50 –

Motor loads

AC-2: slip-ring motors 2 0.65 6 000 4 0.65 50 –

AC-3: squirrel cage motors 2 0.45 6 000 10 for make 0.45 50 make + –

8 for make break 50 make break

AC motor (across-the-line 2 0.40 – 0.50 1 000 LRA (~6) 0.40 – 0.50 50 –

switching)

Elevator control, AC motor 2 0.50 500 000 n/a n/a n/a "Elevator duty"

AC-4: plugging, inching, jogging 6 0.45 6 000 12 for make 0.45 50 make + –

10 for make break 50 make break

Lamps and lighting loads

AC-5a: electric discharge lamps 2 0.45 6 000 3 0.45 50 "Ballast"

AC-5b: incandescent lamps 1 Lamp 6 000 1.5 Lamp 50 "Tungsten"

Transformers and capacitors

AC-6a: transformers The manufacturer shall verify the AC-6a rating by testing with a transformer, or may derive the rating from the values for AC-3.

AC-6b: capacitors Capacitive ratings may be derived by capacitor switching tests or assigned on the basis of established practice and

experience.

Capacitive switching (kVar) 1 Capacitor 6 000 1.5 Capacitor 50 –

Hermetic refrigerant compressor motors

AC-8a: hermetic refrigerant 1 0.8 30 000 6 0.45 50 "Hermetic refrigeration

compressor compressor"

AC-8b: hermetic refrigerant 6 0.45 6 000 6 0.45 50 –

compressor (recycle rating)

Note: the information above is an overview of UL 60947-4-1 tables 1, 7, 10, 5.4.1DV.1.1, 8.2.4.1DV.1.1, and 8.2.4.2DV.1.1 and is intended for comparison purposes only.

DC load testing for contactors rated up to 100 A

Harmonized test Rating designation Endurance test Overload test Required load marking

IEC UL CSA Multiple L/R ms Number Multiple L/R ms Number

of current of cycles of current of cycles

General use, non-inductive or slighting inductive loads, resistance furnaces and heaters

DC-1: general use 1 1 6 000 1.5 1 50 –

DC resistance 1 1 6 000 1.5 1 50 "Resistive"

DC resistance air heating 1 1 100 000 1.5 1 50 "Resistance"

Motor loads

DC-3: shunt motors 2.5 2 6 000 4 2.5 50 –

DC motor (across-the-line 2 n/a 1 000 10 n/a 50 –

switching)

Elevator control, DC motor 2 n/a 500 000 Not applicable "Elevator duty" 13

DC-5: series motors 2.5 7.5 6 000 4 15 50 –

Lamps and lighting loads

DC-6: incandescent lamps 1 Lamp 6 000 1.5 Lamp 50 "Tungsten"

Note: the information above is an overview of UL 60947-4-1 tables 1, 7, 10, 5.4.1DV.1.1, 8.2.4.1DV.1.1, and 8.2.4.2DV.1.1 and is intended for comparison purposes only.

1SBC100110S0201