Page 254 - PLC Automation

P. 254

252 MAIN CATALOG PLC AUTOMATION

—

Application descriptions

Safe communication between safety CPUs

using PROFINET/PROFIsafe over 5G

— Real-time exchange of high volume process and Now hybrid interconnected PLC control systems

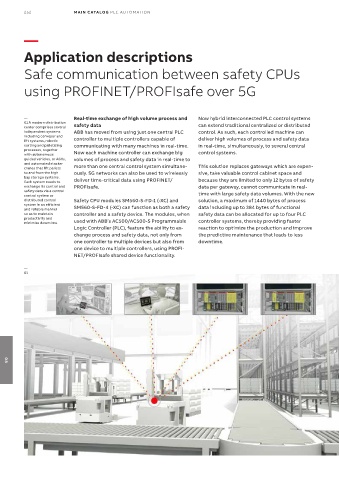

01 A modern distribution safety data can extend traditional centralized or distributed

center comprises several

independent systems ABB has moved from using just one central PLC control. As such, each controlled machine can

including conveyor and controller to multiple controllers capable of deliver high volumes of process and safety data

lift systems, robotic

sorting and palletizing communicating with many machines in real-time. in real-time, simultaneously, to several central

processes, together Now each machine controller can exchange big control systems.

with autonomous

guided vehicles, or AGVs, volumes of process and safety data in real-time to

and automated stacker more than one central control system simultane- This solution replaces gateways which are expen-

cranes that lift pallets

to and from the high ously. 5G networks can also be used to wirelessly sive, take valuable control cabinet space and

bay storage systems. deliver time-critical data using PROFINET/ because they are limited to only 12 bytes of safety

Each system needs to

exchange its control and PROFIsafe. data per gateway, cannot communicate in real-

safety data via a central time with large safety data volumes. With the new

control system or

distributed control Safety CPU modules SM560-S-FD-1 (-XC) and solution, a maximum of 1440 bytes of process

system in an efficient SM560-S-FD-4 (-XC) can function as both a safety data including up to 384 bytes of functional

and reliable manner

so as to maintain controller and a safety device. The modules, when safety data can be allocated for up to four PLC

productivity and used with ABB’s AC500/AC500-S Programmable controller systems, thereby providing faster

minimize downtime.

Logic Controller (PLC), feature the ability to ex- reaction to optimize the production and improve

change process and safety data, not only from the predictive maintenance that leads to less

one controller to multiple devices but also from downtime.

one device to multiple controllers, using PROFI-

NET/PROFIsafe shared device functionality.

—

01

08