Page 762 - Motor protection and control Manual motor starters, contactors and overload relays

P. 762

7/6 ABB MOTOR PROTECTION AND CONTROL

—

Thermistor motor protection relays

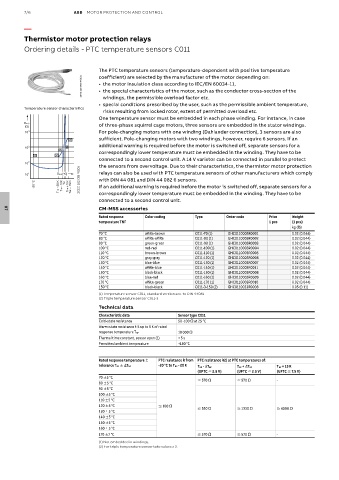

Ordering details - PTC temperature sensors C011

The PTC temperature sensors (temperature-dependent with positive temperature

coefficient) are selected by the manufacturer of the motor depending on:

1SVC 110 000 F0531 • the motor insulation class according to IEC/EN 60034-11,

• the special characteristics of the motor, such as the conductor cross-section of the

windings, the permissible overload factor etc.

• special conditions prescribed by the user, such as the permissible ambient temperature,

Temperature sensor characteristics

risks resulting from locked rotor, extent of permitted overload etc.

One temperature sensor must be embedded in each phase winding. For instance, in case

RPTC of three-phase squirrel cage motors, three sensors are embedded in the stator windings.

[ ]

10 4 For pole-changing motors with one winding (Dahlander connection), 3 sensors are also

sufficient. Pole-changing motors with two windings, however, require 6 sensors. If an

additional warning is required before the motor is switched off, separate sensors for a

10 3

correspondingly lower temperature must be embedded in the winding. They have to be

connected to a second control unit. A 14 V varistor can be connected in parallel to protect

10 2 the sensors from overvoltage. Due to their characteristics, the thermistor motor protection

10 1 TPTC [°C] relays can also be used with PTC temperature sensors of other manufacturers which comply

with DIN 44 081 and DIN 44 082 6 sensors.

-20 °C TNF - 20 K TNF - 5 K TNF TNF + 5 K TNF + 15 K 2CDC 252 068 F0208 If an additional warning is required before the motor is switched off, separate sensors for a

correspon dingly lower temperature must be embedded in the winding. They have to be

connected to a second control unit.

CM-MSS accessories

07

Rated response Color coding Type Order code Price Weight

temperature TNF 1 pce (1 pce)

kg (lb)

70 °C white-brown C011-70 (1) GHC0110003R0001 0.02 (0.044)

80 °C white-white C011-80 (1) GHC0110003R0002 0.02 (0.044)

90 °C green-green C011-90 (1) GHC0110003R0003 0.02 (0.044)

100 °C red-red C011-100 (1) GHC0110003R0004 0.02 (0.044)

110 °C brown-brown C011-110 (1) GHC0110003R0005 0.02 (0.044)

120 °C gray-gray C011-120 (1) GHC0110003R0006 0.02 (0.044)

130 °C blue-blue C011-130 (1) GHC0110003R0007 0.02 (0.044)

140 °C white-blue C011-140 (1) GHC0110003R0011 0.02 (0.044)

150 °C black-black C011-150 (1) GHC0110003R0008 0.02 (0.044)

160 °C blue-red C011-160 (1) GHC0110003R0009 0.02 (0.044)

170 °C white-green C011-170 (1) GHC0110003R0010 0.02 (0.044)

150 °C black-black C011-3-150 (2) GHC0110033R0008 0.05 (0.11)

(1) Temperature sensor C011, standard version acc. to DIN 44081

(2) Triple temperature sensor C011-3

Technical data

Characteristic data Sensor type C011

Cold-state resistance 50 -100 q at 25 °C

Warm-state resistance ± 5 up to 6 K of rated

response temperature T NF 10 000 q

Thermal time constant, sensor open (1) < 5 s

Permitted ambient temperature +180 °C

Rated response temperature w PTC resistance R from PTC resistance R2) at PTC temperatures of:

-20 °C to T NF - 20 K

tolerance T NF w iT NF T NF - iT NF T NF + iT NF T NF + 15 K

(UPTC m 2.5 V) (UPTC m 2.5 V) (UPTC m 7.5 V)

70 w5 °C m 570 q M 570 q -

80 w5 °C

90 w5 °C

100 w5 °C

110 w5 °C

120 w5 °C m 100 q m 550 q M 1330 q M 4000 q

130 w5 °C

140 w5 °C

150 w5 °C

160 w5 °C

170 w7 °C m 570 q M 570 q -

(1) Not embedded in windings.

(2) For triple temperature sensor take values x 3.