Page 312 - Railways Applications Terminal blocks

P. 312

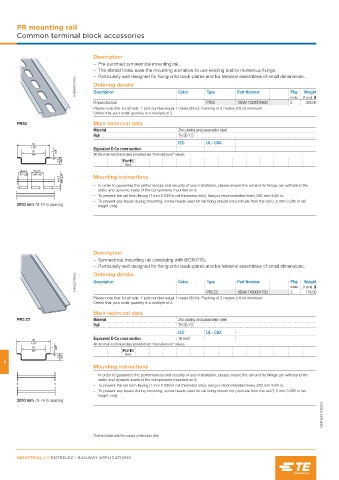

PR mounting rail

Common terminal block accessories

Description

– Pre-punched symmetrical mounting rail,

– The slotted holes ease the mounting and allow to use existing and/or numerous fixings,

– Particularly well designed for fixing onto back-plates and for terminal assemblies of small dimensions.

1SNK500072F0000 Ordering details Color Type Part Number Pkg Weight

Description

meter (1 pce) g

Prepunched rail PR30 1SNA173220R0500 2 328.00

Please note that for all rails: 1 part number equal 1 meter (39 in). Packing of 2 meters (78 in) minimum.

Check that your order quantity is a multiple of 2.

PR30 Main technical data

Material Zinc plating and passivation steel

Rail TH 35-7.5

IEC UL - CSA

Equivalent E-Cu cross section

All the main technical data provided are "manufacturer" values.

RoHS

Mounting instructions

– In order to guarantee the performances and security of your installation, please ensure the rail and its fixings can withstand the

static and dynamic loads of the components mounted on it;

– To prevent the rail from flexing (1 mm 0.039 in rail thickness only), fixing is recommended every 250 mm 9.84 in;

– To prevent any issues during mounting, screw heads used for rail fixing should not protrude from the rail (7,5 mm 0.295 in rail

2000 mm 78.74 in spacing height only).

Description

– Symmetrical mounting rail complying with IEC60715,

– Particularly well designed for fixing onto back-plates and for terminal assemblies of small dimensions.

1SNK500073F0000 Ordering details Color Type Part Number Pkg (1 pce) g

Description

Weight

meter

1SNA174300R1700

PR3.Z2

Please note that for all rails: 1 part number equal 1 meter (39 in). Packing of 2 meters (78 in) minimum. 2 718.00

Check that your order quantity is a multiple of 2.

Main technical data

PR3.Z2 Material Zinc plating and passivation steel

Rail TH 35-7.5

IEC UL - CSA

Equivalent E-Cu cross section 16 mm²

All the main technical data provided are "manufacturer" values.

RoHS

9

Mounting instructions

– In order to guarantee the performances and security of your installation, please ensure the rail and its fixings can withstand the

static and dynamic loads of the components mounted on it;

– To prevent the rail from flexing (1 mm 0.039 in rail thickness only), fixing is recommended every 250 mm 9.84 in;

– To prevent any issues during mounting, screw heads used for rail fixing should not protrude from the rail (7,5 mm 0.295 in rail

height only).

2000 mm 78.74 in spacing

1SNK160017S0201

Technical data valid for copper conductors only.

INDUSTRIAL /// ENTRELEC - RAILWAY APPLICATIONS