Page 234 - PLC Automation

P. 234

232 MAIN CATALOG PLC AUTOMATION

—

Application descriptions

Tunnel automation with AC500

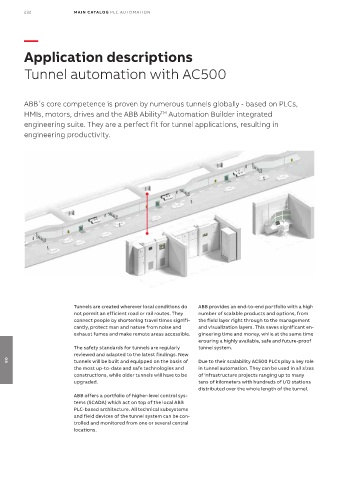

ABB´s core competence is proven by numerous tunnels globally - based on PLCs,

HMIs, motors, drives and the ABB Ability Automation Builder integrated

TM

engineering suite. They are a perfect fit for tunnel applications, resulting in

engineering productivity.

Tunnels are created wherever local conditions do ABB provides an end-to-end portfolio with a high

not permit an efficient road or rail routes. They number of scalable products and options, from

connect people by shortening travel times signifi- the field layer right through to the management

cantly, protect man and nature from noise and and visualization layers. This saves significant en-

exhaust fumes and make remote areas accessible. gineering time and money, while at the same time

ensuring a highly available, safe and future-proof

The safety standards for tunnels are regularly tunnel system.

reviewed and adapted to the latest findings. New

tunnels will be built and equipped on the basis of Due to their scalability AC500 PLCs play a key role

08

the most up-to-date and safe technologies and in tunnel automation. They can be used in all sizes

constructions, while older tunnels will have to be of infrastructure projects ranging up to many

upgraded. tens of kilometers with hundreds of I/O stations

distributed over the whole length of the tunnel.

ABB offers a portfolio of higher-level control sys-

tems (SCADA) which act on top of the local ABB

PLC-based architecture. All technical subsystems

and field devices of the tunnel system can be con-

trolled and monitored from one or several central

locations.