Page 223 - PLC Automation

P. 223

221

—

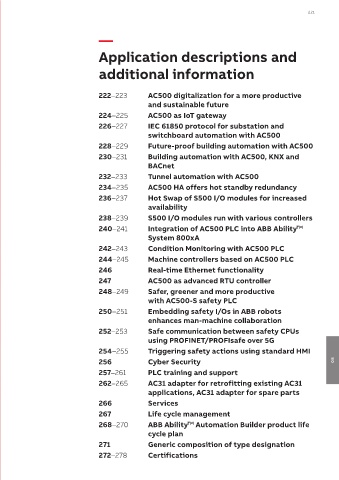

Application descriptions and

additional information

222–223 AC500 digitalization for a more productive

and sustainable future

224–225 AC500 as IoT gateway

226–227 IEC 61850 protocol for substation and

switchboard automation with AC500

228–229 Future-proof building automation with AC500

230–231 Building automation with AC500, KNX and

BACnet

232–233 Tunnel automation with AC500

234–235 AC500 HA offers hot standby redundancy

236–237 Hot Swap of S500 I/O modules for increased

availability

238–239 S500 I/O modules run with various controllers

240–241 Integration of AC500 PLC into ABB Ability

TM

System 800xA

242–243 Condition Monitoring with AC500 PLC

244–245 Machine controllers based on AC500 PLC

246 Real-time Ethernet functionality

247 AC500 as advanced RTU controller

248–249 Safer, greener and more productive

with AC500-S safety PLC

250–251 Embedding safety I/Os in ABB robots

enhances man-machine collaboration

252–253 Safe communication between safety CPUs

using PROFINET/PROFIsafe over 5G

254–255 Triggering safety actions using standard HMI

256 Cyber Security 08

257–261 PLC training and support

262–265 AC31 adapter for retrofitting existing AC31

applications, AC31 adapter for spare parts

266 Services

267 Life cycle management

268–270 ABB Ability Automation Builder product life

TM

cycle plan

271 Generic composition of type designation

272–278 Certifications