Page 240 - PLC Automation

P. 240

238 MAIN CATALOG PLC AUTOMATION

—

Application descriptions

S500 I/O modules run with various

controllers

S500 remote I/O Easy engineering

The availability of different fieldbus communi- The electronic configuration files that are

cation interfaces makes it easy to use S500 I/O provided by ABB for different fieldbus systems

modules as remote I/O for nearly any PLC and make it easy to configure the S500 remote I/O

PC. The S500 remote I/O station consists of a station in your engineering tool. The files such as

communication interface and I/O modules. The GSD and GSDML are available for download at

smallest configuration can be just the communi- www.abb.com/plc. For Modbus TCP remote I/O

cation interface with the onboard I/O channels. stations a dedicated configurator is included in

Communication interfaces are available for the Automation Builder and for larger applications a

following fieldbuses: Bulk Data Manager tool can be used.

• PROFIBUS AC500-eCo CPU as S500 remote I/O

• PROFINET/PROFIsafe When the AC500-eCo compact CPU is used as

• EtherCAT remote I/O, it can be programmed with Automa-

• Modbus TCP tion Builder for local intelligence while communi-

• CANopen cating via the open protocols Modbus TCP or

• ABB CS31 System Bus Modbus RTU with a CPU that will then be the

master of this intelligent remote I/O station. The

AC500-eCo CPU can be expanded by I/O modules

from the S500 and S500-eCo range.

—

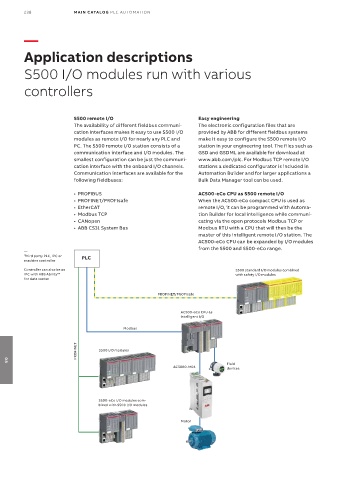

Third party PLC, IPC or PLC

machine controller

Controller can also be an S500 standard I/O modules combined

IPC with ABB Ability™ with safety I/O modules

for data center

PROFINET/PROFIsafe

AC500-eCo CPU as

intelligent I/O

Modbus

PROFINET S500 I/O modules

Field

08

ACS880-M04 devices

S500-eCo I/O modules com-

bined with S500 I/O modules

Motor