Page 241 - PLC Automation

P. 241

APPLIC ATION DESCRIPTIONS AND ADDITIONAL INFORMATION 239

S500 remote I/O with Modbus TCP S500 remote I/O with PROFINET/PROFIsafe

ABB provides a configurator in the Automation Simply extend your control system with ABB stan-

Builder tool, which allows the configuration of dard and safety I/Os to simplify wiring, reduce

Modbus TCP I/O stations with the communica- operating costs and benefit from the unique

tion interfaces CI521-MODTCP or CI522-MODTCP features of our safety I/O portfolio to increase

in the same style as the AC500 configuration. For the productivity of your machines.

larger applications a Bulk Data Manager tool can

be used. The configuration can be stored in the For more information about safety applications,

communication interface, which allows using please see application description Embedding

the configured station with any PLC or PC that safety I/Os in ABB robots on page 250.

supports Modbus TCP. This e.g. allows the use

directly on other controllers or monitoring S500 in hybrid applications with

systems as e.g. ABB Ability™ Data Center Auto- AC 800M Controller

mation or external systems. The communication interfaces for PROFIBUS and

PROFINET facilitate the integration of S500 as

Thanks to the Modbus feature that allows remote I/O stations in the System 800xA AC 800M

several masters to exchange data with the same family of controllers. System redundancy is

slave, it is possible to use the I/O station as supported with PROFINET. The configuration is

shared devices with up to 10 PLC CPUs. integrated into the Control Builder M engineering

tool.

The Modbus masters can access the process data

of the I/O stations in two different ways: Hot swap of S500 I/O modules is possible when

• Fixed mode: each I/O module in the station these are mounted on hot swap terminal units.

uses a separate register address range, which

requires separate Modbus read/write opera-

tions for the modules in the station.

• The dynamic mode allows to pack the data of all

I/O modules in the station in one data structure

that can be exchanged in one single read/write

operation.

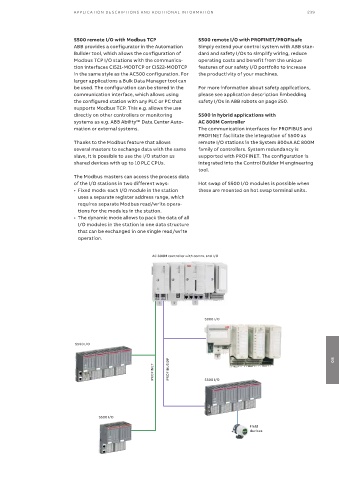

AC 800M controller with comm. and I/O

S800 I/O

S500 I/O

PROFINET PROFIBUS DP S500 I/O 08

S500 I/O

Field

devices